Feature:

What are Spiral Wound Gaskets?

A Spiral Wound Gasket is the most common metallic gasket used in industrial plants. A properly selected and installed spiral wound gasket can withstand high temperatures and pressures, preventing leaks throughout their intended lifespan.

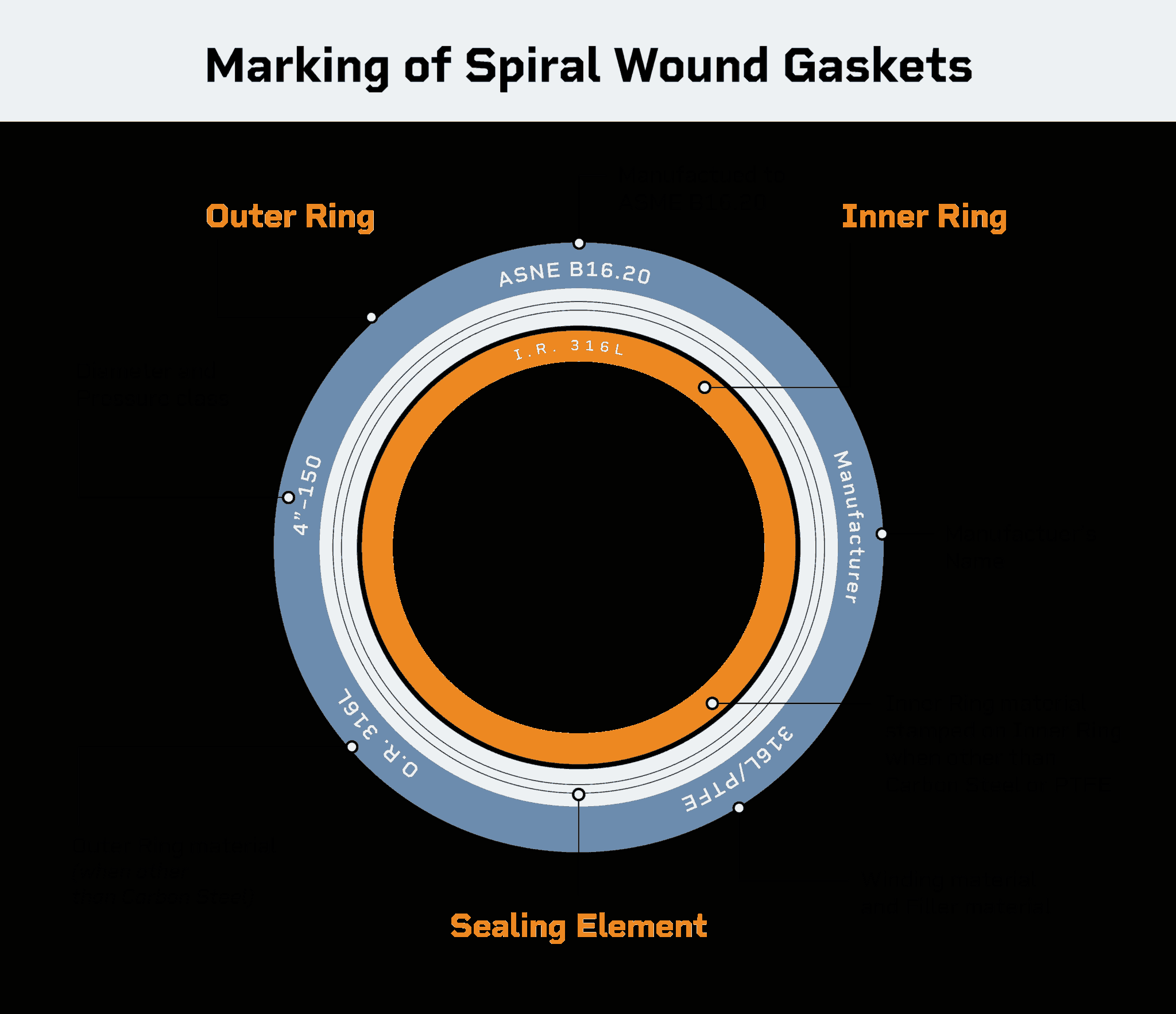

A spiral wound gasket consists of three elements:

Outer ring. Made of carbon steel, this outer ring is sometimes called the centering ring or guide ring. It’s used to center the gasket when you insert it into a bolted flange joint.

Inner ring. The inner ring is pivotal for the gasket because it prevents windings from buckling inside the pipe. When a gasket buckles, parts of it get sucked into the pipe. From there, pieces of the gasket will typically flow through the pipeline until they get caught on something. Often, they’ll get wrapped around rotating equipment like a pump. The mess that results is known as a “bird’s nest.” Inner rings help you avoid this problem.

Sealing element. As you might guess from the name, the sealing element creates the seal that prevents leaks. A sealing element encompasses both windings and filler material. Most spiral wound gaskets in oil and gas refineries will use a flexible graphite filler material rated for high temperatures. A flexible graphite filler also allows the gasket to be more tolerant of flange distortion and joint misalignment. Polytetrafluoroethylene (PTFE) is another common filler material. PTFE is not rated for high-temperature applications, however. Meanwhile, most winding materials in refineries will be stainless steel and monel.

Description:

|

ITEM |

STYLE |

FLANGE |

FOR EXAMPLE |

|

BASIC TYPE SWG |

GS001 |

TONGUE AND GROOVE |

304/PTFE |

|

SWG WITH INNER RING |

GS001IR |

MALE AND FEMALE |

304 304/FG |

|

SWG WITH THE OUTER RING |

GS001CR |

RAISED FACEFLAT FACE |

304/ASB CS |

|

SWG WITH INNER &OUT RINGS |

GS001IC |

|

304 304/FG CS |

|

SWG FOR HEAT EXCHANGER |

GS001H |

HEAT EXCHANGER |

304/FG WITH 1 BAR OF DJ |

|

SPECIAL SHAPE SWG |

GS001S |

SPECIAL |

OVAL |

Application:

Spiral-wound graphite gaskets are widely used in piping, fittings, apparatusand plant engineering where high mechanical, thermal and chemicalstresses are encountered, and wherever fibre (FA) and graphite (GR)materials can no longer be used. This is the case for example for pressuresup to and above 300 bar, and temperatures up to and above 550 ℃,particularly with extreme changes in pressure and temperature.Whilst the oriainal classical application was in the petrochemical industry,today there is hardly any industrial sector that does not make use of spiralwound graphite gaskets. One of the main applications is steam sealing athiah pressures or temperatures(superheated steam).Spiral-wound graphite gaskets will tolerate certain irregularities and flangeor sealing face deformations more than most other gasket types.

Metal spiral wound gasket:

Metal wound gasket is a kind of sealing gasket widely used, which isthe best resilient gasket in the semi-metallic sealing gasket, and thewinding gasket is made of high-quality SUS304, SUS316 "V" shapedor "W" shaped metal strip and other alloy materials with residualgraphite,asbestos, PTFE,and non-asbestos soft materials alternatelyoverlapping and spiral winding

Sealpilot spiral wound pads are precision-engineered solutions forflange joints, heat exchangers, manholes and other high-temperaturehigh-pressure applications that are resistant to virtually all knowncorrosive and toxic elements.

Related Category:

CGI Spiral Wound Gasket ,CG Spiral Wound Gasket ,Vermiculite Filler Spiral Wound Gasket ,Raw Materials for Spiral Wound Gasket , OFHC Copper Gasket For CF Flanges , Flange lsolation Gasket Kits , Rubber-steel Flange Gaskets , Ring Type Joint Gasket , Kammprofile Gaskets

Related Products:

Monel 400 CGl Spiral Wound Gasket

SS 316L with Graphite Filler Spiral Wound Gasket

Style CGl Spiral Wound Gasket

Duplex 2205 Spiral Wound Gasket

SS 321 Spiral Wound Gasket

INCOLOY 800 Spiral Wound Gasket